Changing Procurement Process at B2B Marketplaces

Covid-19 hit everywhere unexpectedly, Unveiling that companies are not well prepared for the disturbance in their supply chain and are re-evaluating how to obtain materials going forward. Here are the reasons why I think now is an excellent time for building B2B marketplaces.

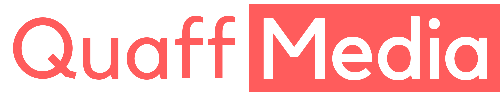

Covid-19 acts as a trigger event for companies to re-evaluate their supply chains

In March, E&Y surveyed more than 2900 executives in 46 countries across different industries. They asked how their decisions were affected by the Covid-19 event on their global supply chain. Only 8% said there was no change. While 52% were taking steps to change and 40% would re-evaluate their supply chain.

So what could be the changes?

Simply put, the changes can be companies looking for alternative ports for shipping, sourcing alternative components, develop dual sourcing strategies, and do critical reviews of their existing suppliers and trade route. In the past, many companies mainly focused on optimizing their supply chain for better efficiency.

But now we might see them shifting towards some more resilient and faster adjustments. For the reactivation of the supply chain and to invest in resilience, Porsche Consulting suggests developing a strategic master plan “to lift the supply chain to a new maturity level” in response to Covid-19.

Differently put, Covid-19 acts as a trigger event for companies to re-evaluate their supply chain and, therefore, new tools that can help companies in sourcing and managing their suppliers have an excellent opportunity. Recently, Sequoia invested $14M in Knowde, a B2B marketplace for chemicals.

Its founder confirmed the pressure of finding new ways to procure and sell due to Covid-19: He said, “Covid-19 is going to be one more trigger event for the chemical companies that they have to go online”. The personal relationships have dried up that drove much of the sales for the chemical business. So the companies need to find a new way to sell to survive.

A horizontal procurement solution is the one that won the heart of enterprise companies in the past.

If we see the past, Horizontal procurement (i.e., The focus is on a wide range of industries) has been the most successful one and mainly focused on selling to enterprise companies. Here are two examples for this:

- With an idea to replace the paper-based and labor-intensive procurement process with software, Ariba was founded in 1996. Within three years after founding, the company went public and scaled from $800k to $274M in revenue within four years. In 2012, the company was acquired by SAP for €4.3bn.

- Berlin-based Scoutbee raised a pretty big series B of $60M last year, which generated a lot of buzz among investors. The two main functions it offers with supply suit discovery are:

a). Streamline (To evaluate and find global suppliers) and

b). DeepSee ( To enrich supplier profile).

Due to services and heavy customization of its procurement software, Ariba’s gross margin decreased from 83% to 46% within seven years. The importance of building customized solutions when selling into large enterprises and how unique companies’ procurement flows can be, demonstrated by the decrement in Ariba’s gross margin.

These procurement solutions are out of reach of most SMBs and are often unaffordable due to the required onboarding effort, complexity, and cost of customization. These companies could benefit from such solutions only at a low cost or if the product can be adapted to their specific workflow. Thus we see more vertical procurement solutions and hence B2B marketplaces than horizontal platforms.

Vertical Procurement Solutions For All Kinds of Businesses

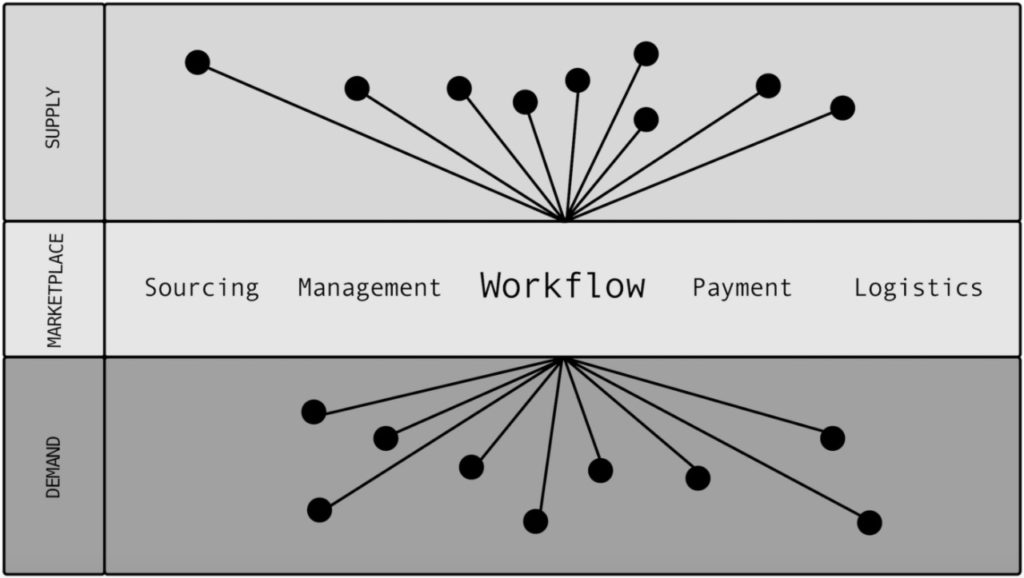

For a specific buying person in any particular industry, B2B marketplaces often build very tailored workflow software, decreasing the need for customization.

Automation and streamlining procurement processes have enormous potential to free up procurement department employees’ time for more strategic purchasing. This time can also be used for new product development and the search for better materials by automating and streamlining procurement processes.

Here are a few examples of these tailored workflows:

- Laserhub: In past years, getting a sheet metal part has taken days and a lot of back and forth with many different suppliers to produce these parts, But with the help of Laserhub, you can upload the CAD file and get an offer from them. They also provide their customers with a CAD guide So that they can manufacture the best possible sheet metal part.

- Faire: If you are a small maker and want to sell your products to any retailer, then you have to take care of the logistics and need to accept the standard payment terms of the industry. After doing all that, makers often don’t get to trade credit giver their small size. But Faire changes everything, i.e., You get free shipping, handling the returns on their end, and they also offer trade credit.

- Zageno: Helping researchers finding the right equipment for their laboratory experiments, Zageno is building a marketplace especially for lab supplies. It eliminates the tough and time-consuming process of comparing different offerings by providing all the information in one place. For unbiased, peer-reviewed ratings, they offer a product rating system.

It's Time to Build

We see this as an exciting opportunity for large and very fragmented industries, to change procurement with such B2B marketplaces. In the last few weeks, the eCommerce penetration has evolved mind-blowingly.

Meanwhile, we can’t say how true this holds for B2B and how sustainable the adaption will be, we can assume that Covid-19 triggers changes in buying behaviors and also make companies shift to more open to trying new things.